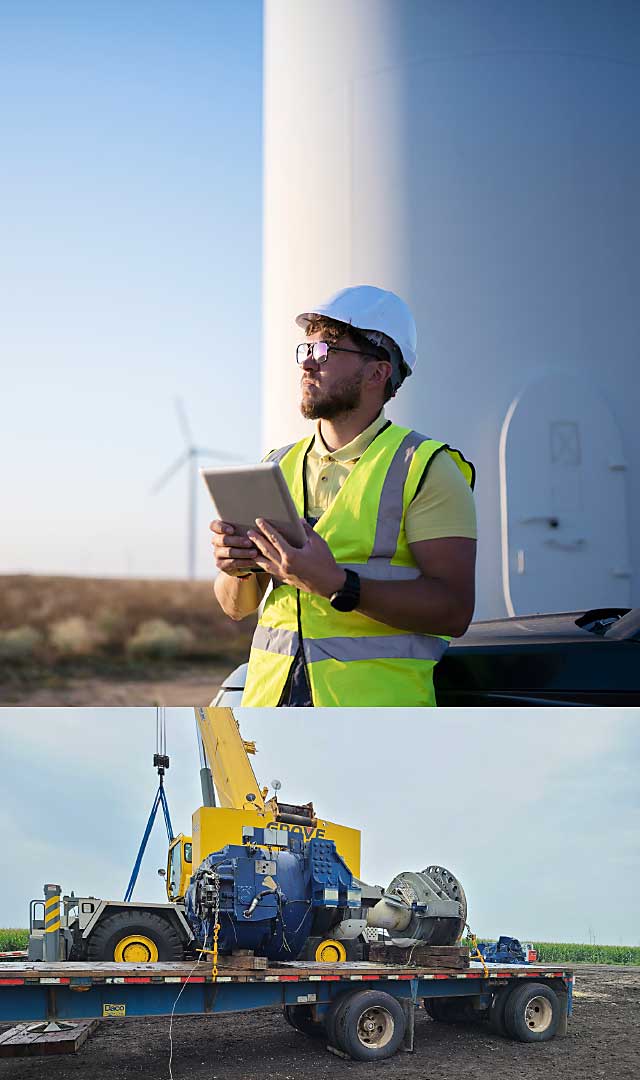

North Coast Enterprise knows wind farms. Our experience in wind turbine project management and services for repower, replacement, end-of-life decommissioning and critical events runs deep. We understand the complexities and challenges—from the mechanical aspects of separating and loading out components, to the environmental aspects of metal and fiberglass recycling and disposal.

We carry out every project with expertise, care, integrity and an unflinching commitment to sustainable solutions.

Wind Turbine Project Management

Our project superintendents:

- Serve as the primary point of contact for the project team

- Supervise our crews

- Ensure that component removal is on schedule

- Minimize disruption to the installation teams

- Manage PODs, incident reports and other documentation

- Ensure the removal of any spills and debris

- Walk the site with the project team prior to demobilization

- Attend all onsite meetings

Our wind turbine project management team also includes a safety manager responsible for the safety and supervision of all North Coast personnel and subcontractors, and a logistics coordinator responsible for managing all trucks onsite.

North Coast’s nationwide network of contractors and union labor, working in conjunction with our own team members, ensures you have the right people in place for every step in the process. Your project gets completed on time and on budget, in compliance with the most rigid quality standards.

Metal Component Disassembly, Loadout, Recycling & Waste Support

For metal component loadout, North Coast provides:

- Engineered lift plans for all components prior to loading

- Component disassembly and separation of steel, fiberglass, copper wire and aluminum

- Cranes, flatbed trucks, lowboy and dump trailers, and other loadout equipment and vehicles required to fulfill the scope of work

- Transportation to processors/mills

- Detailed tracking for all metal components removed from the site

- Light and heavy scale tickets for each load to facilitate tracking and scrap rebate calculations

- Cleanup and treatment of any oil or hazardous fluid spills or leaks caused by our activities

- Fire watch, safety and spill prevention personnel to ensure the safety of our crews and the worksite

Wind Turbine Recycling – Metals

Wind turbine recycling can be a tricky business when you’re dealing with 40-ton drivetrains and other huge, heavy components. North Coast works with a network of recyclers and mills across the United States who have the equipment and experience to safely and efficiently process specialized wind turbine components. We can help you do what’s best for the environment while reducing your project costs by leveraging steel, copper and aluminum scrap rebates to your greatest advantage.

Fiberglass Recycling, Cutting & Removal

In the process of wind turbine component removal, North Coast cuts towers and blades into manageable sections utilizing custom-built diamond-rope or concrete saws that cut the fiberglass quickly, with minimal dust and impact to the project site. These short sections are then easy to load and transport to the processing facility, where they are further processed and recycled through pyrolysis or cement kiln consumption.

North Coast is always sharing ideas and insights with other forward-thinking wind companies. Our goal is to develop new solutions for helping the entire industry reduce levels of unrecyclable waste even further. Together, we can elevate our image as an environmentally responsible industry committed to sustainable energy production.